12 Jun Use Data to Eliminate Significant Cost from Car Fleets

Car fleet supply contracts can be complex and nuanced. The headline deal that is offered when negotiating new supply terms does not always translate into the real-life actual costs incurred when operating the fleet. This is mostly due to the cost-creep that occurs as the contract matures; as unplanned variable costs remain unchecked; and suppliers begin to apply out-of-contract charges and penalties.

Fleetworx understands this. We know that contracts need to be screwed down tight. We know that spend can run out of control if not managed closely. And we know how the supply chain makes their money.

Being armed with data allows the Fleetworx team to anticipate cost-creep. We collect our clients’ data from right across their supply chain and run it through our MIS, Centrax. We then interpret the data and use it to apply the right operational tactics to reduce the clients’ exposure to out-of-contract costs and charges.

And the exposure to those out-of-contract charges is not insignificant.

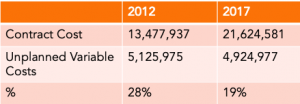

Each year since 2012 Fleetworx have analysed the data of one particular client who operate a large pan-European car fleet. Up to half a million invoice line items are analysed each year and interpreted to understand what percentage are unplanned variable costs.

Beginning in 2012, unplanned variable costs accounted for 28% of the total costs of the fleet of 1,986 vehicles. Charges such as:

- accident damage;

- excess mileage;

- end of contract damage

- hire car costs;

are all variable and extraneous to the contract terms that are negotiated at the beginning of the supply agreement.

Not only are the costs avoidable through the intelligent application of policy and operational best practice, they are also inflated through the often punitive charges and margins that are applied by the suppliers when the costs are incurred.

A major objective of a well-managed supply chain will be the containment and ultimate reduction of these costs, with a plan to ensure the percentage of costs outside of contract are kept to minimum. The higher the percentage of unplanned variable costs, the less controllable the cost-creep and the less manageable the forecasting and planning opportunities.

Fleetworx recognise this opportunity for cost reduction and a more closely managed fleet category. Through the careful analysis of each cost category and the introduction of tactical activities, Fleetworx have been able to reduce the percentage of unplanned variable costs: a major contributor to a more cost-effective and efficient car fleet.

Despite rapid growth of the fleet size and a subsequent increase in fixed costs, the Fleetworx activity meant the percentage of unplanned variable costs was reduced from 28% in 2012 to 19% in 2017.

If you would like your fleet to benefit from systems and processes to manage your unplanned spend then contact Graham Rees for a confidential chat.This fascinating infographic visualises the cost breakdown of a large fleet, highlighting the unplanned variable costs that can cause huge cost creep if they remain unchecked.

Back to Blogs Back to Case Studies List

Sorry, the comment form is closed at this time.